Engineered Flooring

What is Engineered Wood Flooring?

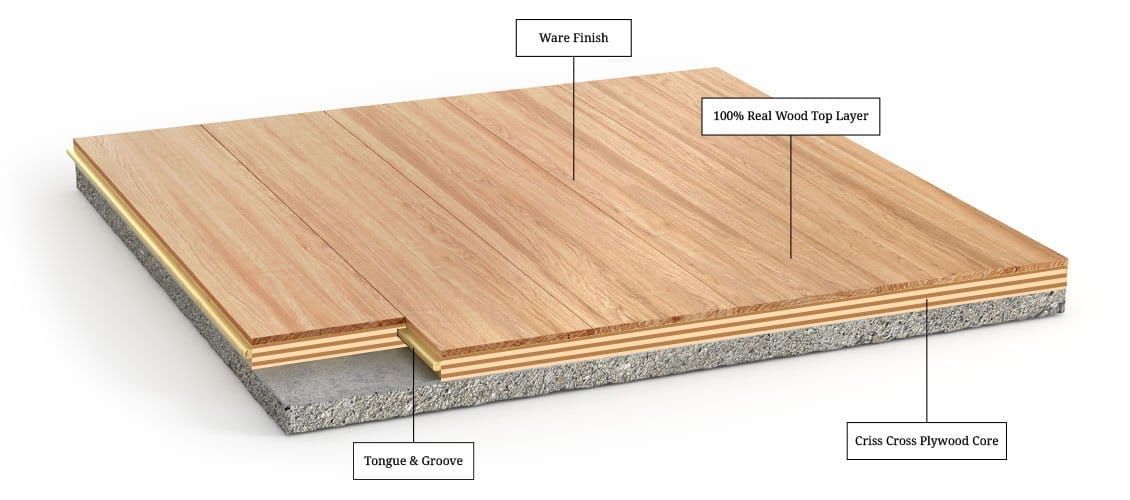

In order to understand what Engineered Wood Flooring is one has to be familiar with its predecessor; Solid Wood Flooring. Solid wood floors are exactly as their name implies, meaning they are made of a solid piece of wood from the top of the plank to its bottom. Engineered wood flooring is real wood flooring as well, however instead of a solid piece of wood from top to bottom its made of several layers of high quality wood veneer and engineered wood composite products that are bonded together using high pressure, heat, and adhesive.

100% Real Wood Top Layer

Engineered wood flooring planks are usually constructed in a few layers. The top layer is made with 100% real high quality sliced cut veneer, which may come in a wide variety of species and textures that can be finished to produce exclusive styles and designs.

Core & Bottom Layers

The Core And Bottom Layers are generally crafted by crisscrossing layers of plywood with soft or hardwood composite products laid with the grain of each layer running perpendicular to the one below it. Bonded by extreme pressure, heat and adhesive, this construction method creates a highly stable core that can often be more dimensional stable then solid wood floors and is less likely to expand, contract or shift when moisture, humidity and temperature fluctuation occurs, Allowing this type of hardwood floor the ability to be installed in more areas of the home like above, on and below grade.

T & G (Tongue and Groove)

Our Engineered Floors are milled with a tongue and groove system for easy installation.

Trim Pieces

Reducer Strip

A teardrop-shaped molding used around fireplaces, doorways, as a room divider, or as a transition between wood flooring and adjacent thinner floor coverings. Fasten down with adhesive, small nails or double-faced tape.

End Cap / Threshold

A molding undercut for use against sliding door tracks, fireplaces, carpet, ceramic tile, or existing thresholds to allow for expansion space and to provide a smooth transition in height difference. Fasten to subfloor with adhesive and/or nails through the heel. Pre-drill nail holes to prevent splitting.

Flush Stair Nosing

A molding undercut for use as stair landings trim, elevated floor perimeters, and stair steps. Fasten down firmly with adhesive and nails or screws. Pre-drill nail holes to prevent splitting.

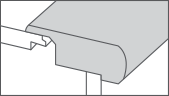

Overlap Stair Nosing

Similar to the flush stair nose however this piece will overlap the flooring plank at the edge of the stair.

Quarter Round

A molding used to cover expansion space next to baseboards, case goods, and stair steps. Pre-drill and nail to the vertical surface, not into the floor.

Wall/Shoe Base

A molding used when a base is desired. Used to cover expansion space between the floor and the wall. Pre-drill and nail into the wall, not the floor.

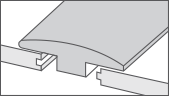

T-Molding

A molding used as a transition piece from one rigid flooring to another of similar height or to gain expansion spaces. Fasten at the heel in the center of the molding. Additional rigid support may need to be added to the heel of the molding dependent upon the thickness of the goods covered. Do not use this molding as a transition to carpet.

FAQ

As mentioned before, the top layer in engineered wood flooring is made with 100% real wood. Wood is a natural material and as such can contain natural character blemishes such as pinholes, knots and mineral streaks. These can be commonly found in lower grades of engineered flooring as higher grades of flooring go through an extensive sorting process were the planks are thoroughly inspected and only selected pieces are labeled as high grade or select & better (See Engineered Flooring Grades for more information).

Color Variation is directly tied to the species of the wood used to produce the floor, as exotic wood species will have more color variation than domestic species and how susceptible the wood is to the stains and colors applied to it. Therefore all grades of hardwood flooring can have color variations, and can be slightly different from dye LOT to dye LOT.

Due to its construction method, Engineered wood flooring can often be more dimensional stable then solid wood floors and is less likely to expand, contract or shift when moisture, humidity and temperature fluctuation occurs. Engineered wood can be an excellent choice for areas where solid hardwood cannot be installed, like in basements, over concrete floors or over radiant heating systems. Further more, Engineered wood floors can be installed above, on and below grade.

Engineered Floors can be installed on many different types of sub-floors ranging from plywood, existing wood floors, OSB subfloors and even concrete. Make sure to refer to the manufacturer installation instructions for more detailed explanation on how to install engineered floor over any of the sub-floors mentioned above.

Engineered hardwood flooring can be installed by using a few different installation methods. It can be stapled and, or nailed to the sub-floor below (In cases where the job-site conditions allow nailing and stapling, such as plywood sub-floors. And, where the width of the flooring planks installed are not grater then 5”. Flooring planks that are wider then 5” are not recommended to be nailed or stapled down as the force of the nails can cause the flooring planks to buckle). Additional installation methods include Glue down and even float.